Sweep Frequency Circuits do NOT Guarantee Even Energy Distribution!

Most ultrasonic cleaning systems today, including those manufactured by Zenith Ultrasonics, include a ‘Sweep Frequency” circuit which sweeps the output frequency to the transducers by 2-3kHz. These Sweep Frequency Circuits are intended to eliminate the areas of in-activity between neighboring standing waves, a technical way of saying that they are supposed to eliminate dead spots or areas that are not as powerful as other areas. However, any simple aluminum foil test can prove that they are only marginally effective at eliminating these dead spots.

What are Standing Waves?

Standing waves are created when vibrations are created in opposite directions at the same frequency and amplitude. In the case of an ultrasonic cleaner, the sound wave is emitted from the tank bottom, and is reflected back downwards from the surface of the bath thereby creating the standing waves. This creates non-moving energy points which are significantly stronger than the amplitude of the emitted wave. This is a very technical way of saying that ultrasonic cleaners only provide the most effective cleaning results at particular locations in the tank. When transducers are mounted onto the bottom of the tank emitting upwards, these points of aggressive scrubbing action are equally-spaced, and the distance between the standing waves is determined by the ultrasonic frequency. The higher the frequency, the closer the standing waves will be to each other.

How do Standing Waves affect Ultrasonic Cleaning?

Standing waves will scrub parts more aggressively at standing wave points, and less aggressively between standing waves. If a part being cleaned has important detail that happens to rest between standing waves after submersion, this area will receive less scrubbing action and may not be cleaned effectively.

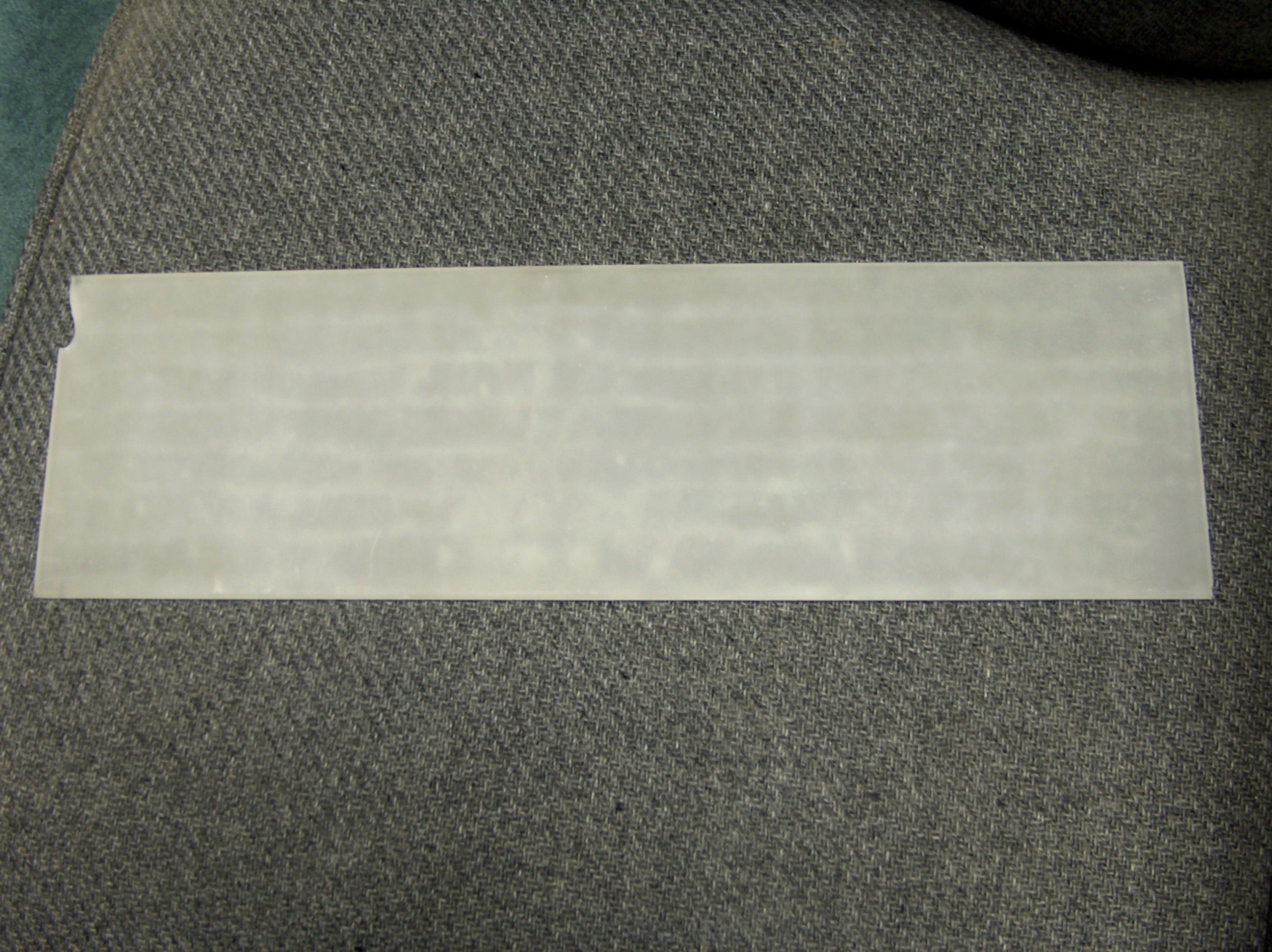

An example of this is shown in the neighboring photo of a glass plate which was etched in a 40kHz ultrasonic cleaner due to over-exposure to the ultrasonic bath. Note the lighter stripes on the surface which are areas where the ultrasonic energy etched the surface. The glass was etched where the ultrasonic energy was strongest; at the standing wave locations. Between these standing waves, no etching of the glass occurred, clearly proving that standing waves are an important issue that must be addressed prior to purchasing equipment.

Why dont sweep frequency circuits work?

Ultrasonic transducers are the sound-emitting devices which are typically mounted on the bottom of the ultrasonic cleaning tank. They are designed to work most effectively at a very specific frequency. If the transducer is powered by a frequency which is different by only 10kHz, power drops more than 50%. This is the reason why sweep frequency circuits only operate at 2-3kHz outside of the transducer’s natural resonance frequency; to ensure that powerful cavitation is still produced at the swept frequency range. More information on transducers can be found in the Learning Center drop-down menu under “Transducer Types“.

By theory, sweeping the output frequency to the transducers causes the standing waves to come closer to one-another, thereby reducing or eliminating standing waves. However, the reality is that the change is so small that it can barely be called effective for most ultrasonic cleaning applications. The problem is, a 2-3kHz change produces such a small change in standing wave position that it is invisible to the naked eye. At 40kHz, standing waves are roughly 1/2″ apart, and at 80kHz, standing waves are roughly 1/4″ apart. What kind of a change can possibly be produced by a total 6kHz shift in frequency? The truth is, barely any change is produced, and any foil test can prove it!

Do sweep frequency circuits improve anything in an ultrasonic cleaner?

Some customers in the high-technology industry have asked if frequency sweep can minimize or eliminate damage on specific sensitive components when cleaned ultrasonically. The answer to this question would depend upon the nature of the product being cleaned. A sweep frequency circuit does create SOME shift in the position of standing waves, albeit not a large amount. However, this small shift may cause damage to be spread out over a larger area if parts are very sensitive. In other cases, damage is prevented, since the base material requires continuous cavitational attack in the same area for it to be damaged.