Ultrasonic Frequency Selection is the Most Important Step in ensuring Success

Choosing the best ultrasonic frequency, or combination of frequencies such as that included in our CROSSFIRE system, is the most important step when purchasing a new ultrasonic cleaner. Ultrasonic frequency selection will play a role in:

- Whether or not the parts are cleaned consistently and successfully

- how loud the system will be during operation

- how long the system will last

- whether or not parts being cleaned are damaged.

The information below will provide you with the properties of each ultrasonic frequency making the job a bit easier. However, keep in mind that Zenith’s engineers will guide you every step of the way, and will test clean your parts to determine which frequency would be best for your application.

20-25kHz ultrasonic cleaners have the most power, but it comes at a price

20-25kHz ultrasonic systems are used when parts are very large and heavy, have highly-bonded contaminants which are difficult to remove, and lack significant detail. The general properties for 20-25kHz ultrasonic cleaning systems are as follows:

- The cleaning action is not very evenly distributed: All ultrasonic cleaners distribute their scrubbing action in a series of horizontal bands which are known as standing waves. Between these bands, only a small percentage of ultrasonic energy is present. Therefore, if a critical part area happens to rest between these standing waves, it may not be cleaned successfully. At 20-25kHz, standing waves are approximately 1″ apart.

- The scrubbing action produced is very strong: This is the strongest ultrasonic frequency you can obtain and as a result, these systems are used to remove highly-bonded contamination such as burned carbon on an engine cylinder head.

- 20-25kHz systems produce the most audible noise: Since these systems operate at frequencies which are close to the human hearing range, they are very loud during operation.

- Transducers do not last as long as higher frequencies: The reason for this is its aggressive force which tends to erode the surface to which the transducers are mounted. This property is called Cavitational Erosion which is shown in the photo to the right.

- 20-25kHz system will damage sensitive metals: The same erosion mentioned above will tend to etch the surface of certain parts, such as highly-polished or machined aluminum components. The lower photo shown to the right depicts such a part which was damaged by a 25kHz ultrasonic cleaning system after only 3 minutes of exposure.

- 20-25kHz systems tend to remove larger particles more efficiently than higher frequency systems, and tend to remove coatings more effectively.

While ultrasonic frequency selection at 25kHz are used to clean heavy and large parts or those with highly-bonded contaminants, some of their negative properties can be reduced by adding a higher frequency to the system such as in our CROSSFIRE Multiple Frequency Ultrasonic System

40kHz is the most common frequency in use

40khz ultrasonic cleaning systems are the most common systems in use. This ultrasonic frequency selection provides a good combination of power and more evenly-distributed energy patterns than the 25kHz ultrasonic systems previously described. However, they also have their limitations and properties as follows:

- 40kHz systems sacrifice power for energy distribution when compared to 25kHz ultrasonic systems.

- More evenly distributed energy improves consistency of cleaning results on smaller parts.

- Dead zones between energy bands (standing waves) are still present although these zones are not as large as those in a 20-25khz system.

- Tanks and transducer radiating surfaces will last longer than 20-25kHz ultrasonic systems but not as long as frequencies above 40kHz.

- 40kHz systems generate significantly less audible noise than 20-25kHz systems but not as low as higher frequency systems.

- 40kHz systems tend to remove particles which are larger than .7 microns in size and larger.

- 40kHz systems are less damaging to sensitive metals but damage may still be produced.

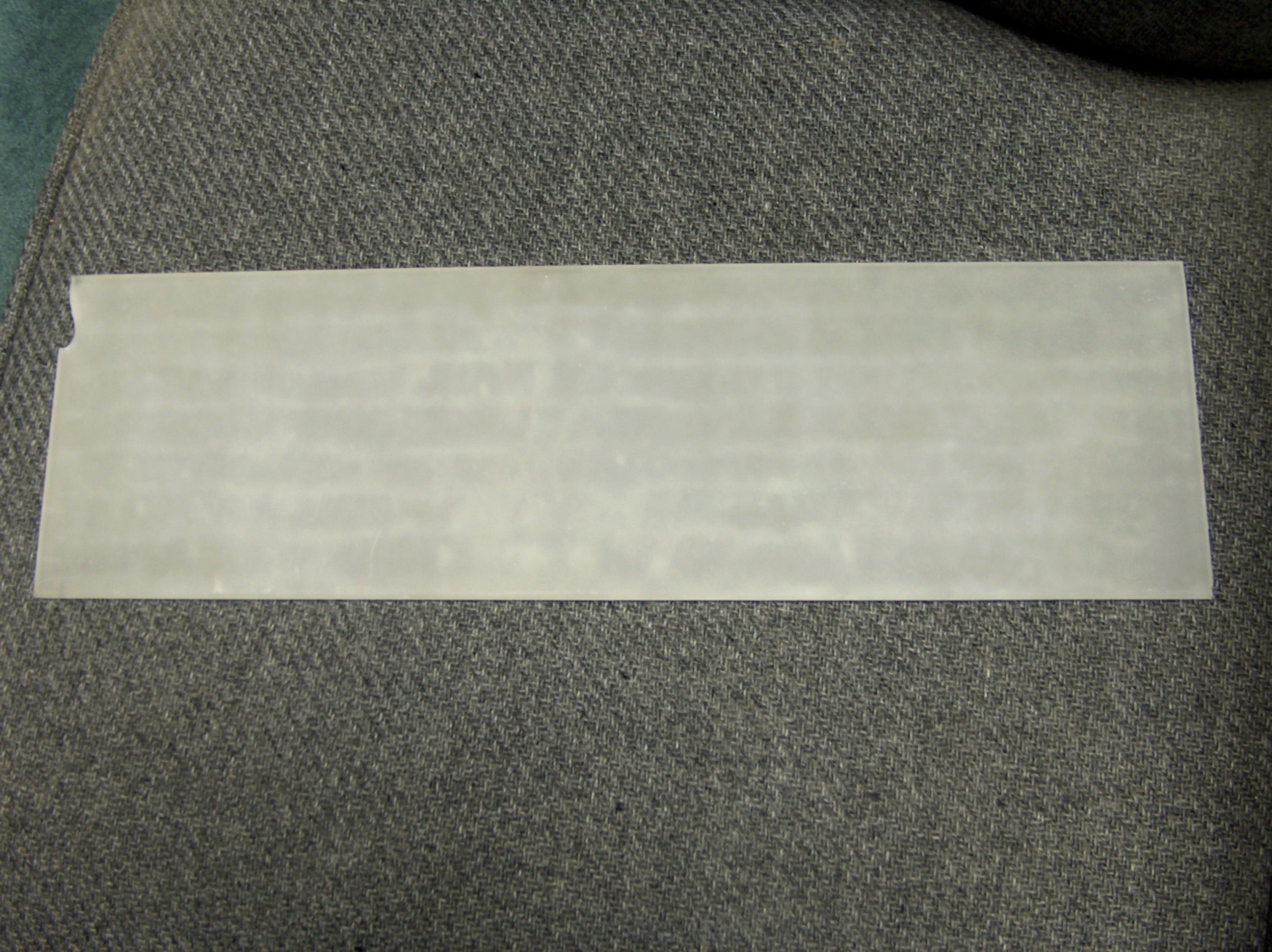

The top photo to the right depicts a glass plate that was etched by overexposure to a 40kHz ultrasonic cleaning system. If you look closely, you will see lighter strips which travel horizontally on the surface of the glass. These are the areas where the ultrasonic system damaged the glass and represents a typical scrubbing pattern produced by a 40kHz ultrasonic system. These standing waves are approximately 1/2″ apart, and you can see why smaller blind holes and detailed areas might still be missed when cleaned with a 40khz system.

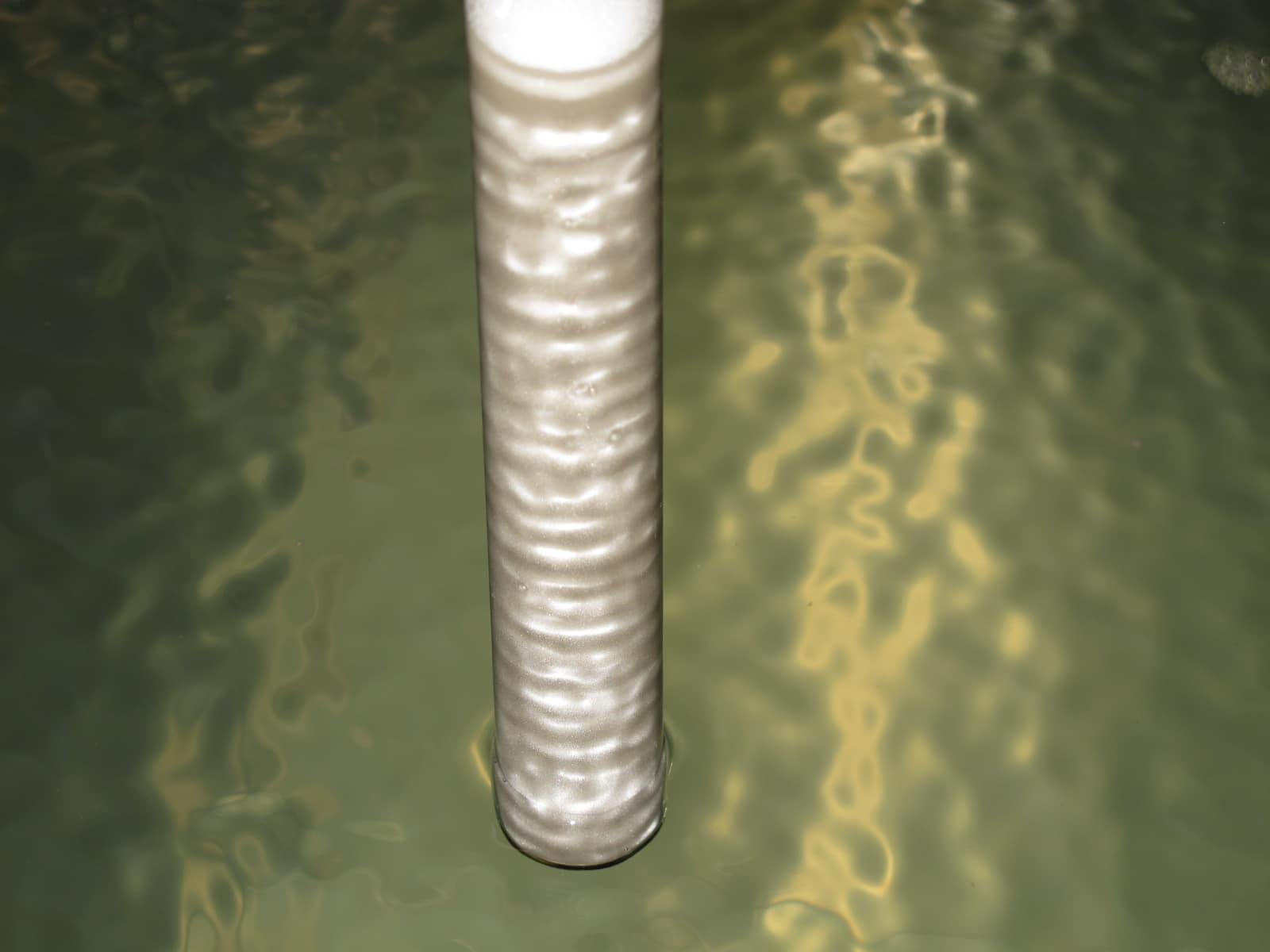

The lower photo to the right depicts Zenith’s patented Ultraprobe Ultrasonic Imaging Device which visually indicates the standing waves produced by any ultrasonic cleaning system, in this case a 40kHz system. The lighter stripes are areas of intense ultrasonic scrubbing action while the darker areas represent areas where little ultrasonic energy is present.

68-80kHz ultrasonics produce evenly distributed scrubbing action with less scrubbing force

The ultrasonic frequency selection at 68-80kHz were pioneered by Zenith Ultrasonics. Prior to the development and introduction of the Ultraprobe Ultrasonic Demonstration Device, there was no way to characterize the scrubbing action in an ultrasonic bath. At that time, Zenith was the only manufacturer offering a frequency above 40kHz, and our competitors contention was that these frequencies were useless as a result of having low scrubbing force. After we demonstrated the Ultraprobe at an IMTS trade show in Chicago, things changed drastically, and within 1 year, every major manufacturer of ultrasonic cleaners offered frequencies above 40kHz. Today, ultrasonic cleaners are available at ultra-high frequencies above 400kHz, sold by the same PhD’s which claimed that anything above 40kHz was useless.

68-80kHz ultrasonic cleaners sacrifice scrubbing force for even energy distribution. Standing waves are less than 1/4″ apart from one another and this leads to extremely evenly-exposed cleaning action on the surface of parts being cleaned. However, this frequency also has its limitations and properties, as follows:

- Lower scrubbing force is present: Even though the scrubbing action is very evenly distributed, scrubbing force is reduced. As a result, this frequency is normally used to clean lighter part loads with lightly bonded contaminants such as oils, coolants, metal fines and chips, and others.

- Cleaning agent is more important: Due to the reduced scrubbing force, the cleaning fluid’s ability to reduce the bond between the contaminant and part is more important.

- 80kHz systems are very quite during operation: Only a gentle buzzing sound is noticed.

- Addresses smaller particle sizes more efficiently: Higher frequencies such as this tend to address smaller particles more effectively such as those that are .2 microns and smaller.

- Less damaging to parts and components: Machined or polished aluminum parts or others that are sensitive to ultrasonic attack require can be exposed for longer periods of time before damage is evident.

- Tanks and transducers last longer: The lower power levels produced by these systems lack the power to aggressively attack the tank or transducer radiating surfaces so they tend to last for decades.

The upper photo to the right depicts the Ultraprobe measuring an 80kHz ultrasonic cleaning tank. Note how close together the standing waves are. Smaller parts cleaned in smaller batches are perfect candidates for this frequency, but improvement in power could be produced if a 40/80kHz CROSSFIRE system were used. The Crossfire system includes the power of 40kHz and the even energy distribution of 80kHz in the same bath.

Frequencies above 80kHz address a very small percentage of cleaning applications

Ultrasonic frequencies above 80kHz address a very small percentage of cleaning applications, primarily those where parts are so sensitive to ultrasonic attack that these frequencies are required. Zenith provides 130kHz and 170kHz ultrasonic systems for such applications. These systems are highly limited due to the scrubbing force being so low in these systems. They can remove dust and particles that are resting on the surface with no bond but do not have the force required to remove most contaminants found. As such, they are used for applications such as hard disk cleaning and electronics cleaning since these components are highly sensitive to ultrasonic attack. These systems offer the following limitations and properties:

- Very weak scrubbing force that is VERY evenly distributed: Cannot remove most industrial contaminants effectively.

- Only effective with very light part loading: The number of parts and weight of parts in the basket must be reduced.

- Systems are capable of removing very small particles, significantly smaller than the .2 micron efficiency of the 80kHz system

- Generate no noise during operation.

- Transducer output angle is greatly reduced: The output of the transducers has a very small angle. As a result, transducers must be mounted close to each other or parts must by a few inches above the transducers in order to be evenly exposed.

- Transducer radiating surfaces do not erode at all due to lack of scrubbing force.

- Damage to parts being cleaned is virtually non-existent.

- Cleaning systems can be VERY expensive: In the case of very high frequencies above 170kHz, tanks are typically made of quartz and even small tanks cost tens of thousands of dollars.

The photo to the right depicts the Ultraprobe exposed to a 170kHz ultrasonic cleaning system. As you can see, the standing waves and scrubbing bands are nearly in contact with one another. There are no areas where scrubbing action is not present, but the lack of scrubbing force limits the use of these systems to a very small number of applications.